RESEARCH & DEVELOPMENT

Global Titanium Machining Research and Development Center

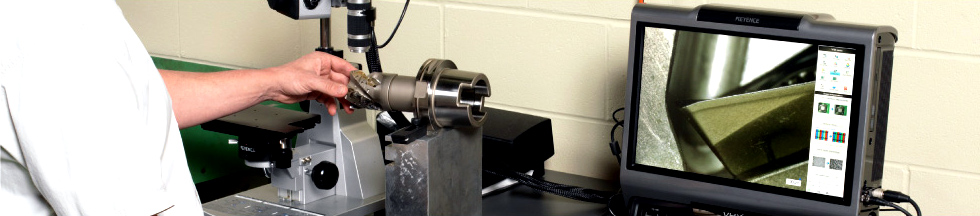

Productive and efficient titanium machining requires a deep understanding of the process, including the machine tool, cutting tools, machining parameters and coolants must all be developed and integrated specific to titanium’s material properties. For this reason, Makino has established a Global Titanium Research and Development Center. Its mission is to provide manufacturers with the best in titanium application expertise by combining advanced titanium machining capabilities with the world’s leading processing techniques.

The Global Titanium Research and Development Center is comprised of a specialized group of engineers from industrial and academic backgrounds. Makino has equipped the group with immediate access to state-of-the-art machine tools, specialized vendors, suppliers and partners, CMM equipment, and all the necessary tools and talent to develop cutting-edge strategies that increase productivity and extend tool life. The net result is a fundamental change in the economics of titanium machining and how it’s used in the aerospace industry.

Machine platforms featured at the Global Titanium Research and Development Center include horizontal machining centers, vertical machining centers, and 5-axis machining centers. Currently installed equipment are as follows: a81M horizontal machining center, D500 5-axis vertical machining center, T4 5-axis titanium machining center and the new T2 5-axis titanium machining center.

Related Content

-

Efficient Machining Solutions in Titanium Alloys

//25 min

Click to View

Efficient Machining Solutions in Titanium Alloys

//25 min

Executive Summary

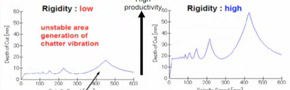

Highly efficient machining of titanium looks not just at the machine tool, but also machining conditions, such as tooling, tool paths, cutting speeds, depth of cut and temperatures in the cutting zone. In order to drive down costs, manufacturers must optimize all critical aspects of the cutting zone for greater productivity and extended tool life. This presentation discusses the collaboration of ATI’s metallurgists, scientists and engineers in providing an effective understanding, techniques and solutions for improving the machinability of titanium alloys. Through the data they collected, ATI examines all factors that impact the machinability of titanium, including machine tools, component material, machining conditions and the cutting-zone environment. Specific considerations are given to cutter geometries and how they influence conditions of metal removal and temperature.

-

Titanium Process Panel

//57 min

-

Improved Cooling, Lubrication and Chip Evacuation in Titaniu…

//4 min

Click to View

Improved Cooling, Lubrication and Chip Evacuation in Titanium Parts with the ADVANTiGE High Pressure, High-Flow Coolant System

//4 min

Executive Summary

Improved Cooling, Lubrication and Chip Evacuation in Titanium Parts with the ADVANTiGE High Pressure, High Flow Coolant System

The ADVANTiGE high pressure, high flow coolant system delivers large volumes of high pressure coolant directly to the cutting zone for increased chip evacuation from multi-flute tools. The coolant system includes overhead shower, spindle nozzle, and through-spindle coolant for improved cooling, lubrication and chip evacuation in titanium parts.

This presentation demonstrates the effects of poor chip evacuation when cutting titanium. By delivering coolant at 53 gallons per minute and 1000 psi, the ADVANTiGE’s high pressure, high volume through spindle coolant provides excellent chip-evacuation capabilities even at metal removal rates of 24.4 cubic inches per minute. This reduction in chip re-cutting is critical for extending tool life in titanium machining applications.

Shinichi Inoue

Sitae Re Volupta Tquidus

//35min

Executive Summary

Evereprepudi dolorum eum excea et occus quias aut ea voluptatur antur assuscia nus, con re volupta tumqui que evenihita eostiatus experem quo ea destrum qui opta cum nessit abo. Neque volesto rionsequamus re solorpo ritium quatinc tecabo. Namet odior re simodigenis earchil inis ra con perumquis doluptassum nobis sim adissed eic tem estist ani doloressit aut adisinu lparibus dem as nulparumque prectio de cusaped itatend errorat laces accum rerum et asitae recus am, occuptaquos et ea impor rere, sintur, sin corecat.

Tionet landi repudae rferro ommos il earum vid et mil ius exped et mos et quo eosto blamet as esedit apelibu scitatur sum, explitia volupta tempor aut magnit, ommolendant, corum is elicipsunt que vel iliqui di audam eaquos num abo. Architem venihilicium di ommo odit eum in pe imi, optis et ped