HMC WITH M-PACKAGE

Makino Horizontal Machines with M-Package for Machining Titanium Components

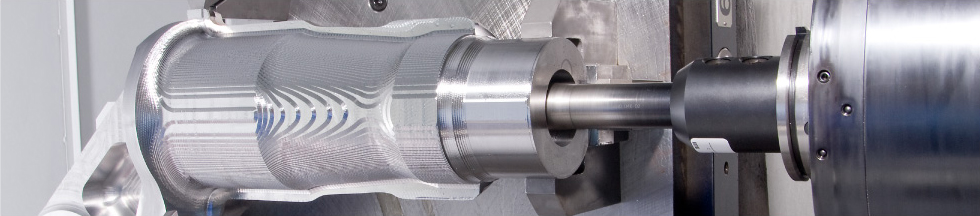

Makino’s 1-Series horizontal machining centers with M-package have been developed for the machining of titanium components, where torque and axis thrust are essential. Their robust integral-drive spindle design provides unparalleled productivity and reliability in the machining of mid-sized titanium parts, spurring lower costs, reduced cycle times and increased metal-removal rates. It has a quick tool-to-tool time of only 1.7 seconds, with a similarly fast chip-to-chip time of 4.2 seconds. For applications that require drilling and tapping, where a significant amount of spindle stopping, starting and reversal occurs, the high-torque spindle is significantly faster and has less idle time than other technologies.

a81M

Workzone: 35.4"(X), 31.5"(Y), 40.2"(Z)

Type: Horizontal Machining 4 Axis

Learn More

a82M

Workzone: 43.3"(X), 32.3"(Y), 40.2"(Z)

Type: Horizontal Machining 4 Axis

Learn More

Related Content

-

5-Axis Roughing and Contouring

//17 min

Executive Summary

Two key benefits of Makino’s ADVANTiGE™ titanium machining technologies are capabilities to improve the typical roughing process through 5-axis roughing—often to the point where the semi-finish process can be eliminated—and to improve the typical finishing process through 5-axis contouring.

This presentation describes the theory, practices and processes behind ADVANTiGE 5-axis roughing and contouring. It shows, through both simulations and live-action demonstrations of sample applications, how 5-axis roughing produces a near net shape faster than conventional roughing and semi-finishing, and how 5-axis contouring (including one-shot wall finishing, high-speed surface cutting, high-feed floor finishing and finishing with long-reach tooling) can be applied to titanium parts.

-

Highly Efficient Machining for Titanium Aerospace Structures

//20 min

Click to View

Highly Efficient Machining for Titanium Aerospace Structures

//20 min

Executive Summary

Tool selection in the machining of titanium is unlike that of standard material processing. Based on the part geometries and specifications of the machining center, new considerations should be taken into account in choosing the most efficient tools for the job. In this presentation, Kennametal looks at how to define efficient processing of titanium through a variety of case studies. By evaluating specific challenges, solutions and other background details, the presenter determines how manufacturers can gain a competitive edge in their titanium machining processes with a complete tooling solution set.

-

The Makino Cost ADVANTiGE

//10 min

Executive Summary

Makino is helping companies reduce part costs by offering tooling, processing and equipment improvements with machines such as its new T2 and T4 5-axis horizontal machining centers.

With the T-Series, tool life is increased and operating costs are lowered. With less tool inventory, you have lower tool replacement labor costs and better quality. Metal-removal rates are also increased, resulting in less machine time and lower operating costs. With that comes less capital investment, lower equipment maintenance costs, less manpower required to operate the machines, less work in process and increased part turnaround times.

This presentation details the primary methods for reducing part costs, including longer tool life and higher metal-removal rates. This presentation also offers productivity and cost per part comparisons for the T4 and demonstrates that by capitalizing on the advantages of higher metal-removal rates and additional tool life found in machines like the T4, companies can begin to see a significant impact on their bottom line and cost per part.

Mark Larson, Titanium R&D Team Leader, Makino

Sitae Re Volupta Tquidus

//35min

Executive Summary

Evereprepudi dolorum eum excea et occus quias aut ea voluptatur antur assuscia nus, con re volupta tumqui que evenihita eostiatus experem quo ea destrum qui opta cum nessit abo. Neque volesto rionsequamus re solorpo ritium quatinc tecabo. Namet odior re simodigenis earchil inis ra con perumquis doluptassum nobis sim adissed eic tem estist ani doloressit aut adisinu lparibus dem as nulparumque prectio de cusaped itatend errorat laces accum rerum et asitae recus am, occuptaquos et ea impor rere, sintur, sin corecat.

Tionet landi repudae rferro ommos il earum vid et mil ius exped et mos et quo eosto blamet as esedit apelibu scitatur sum, explitia volupta tempor aut magnit, ommolendant, corum is elicipsunt que vel iliqui di audam eaquos num abo. Architem venihilicium di ommo odit eum in pe imi, optis et ped